Our offer

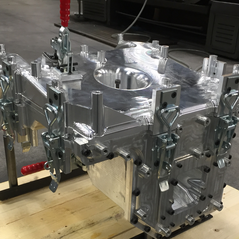

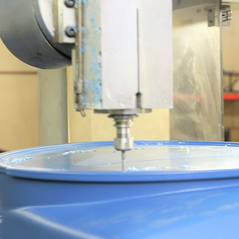

This includes all from project management, construction of mould and product, production, full assembling to logistics.

To involve us in an early stage of the project, means that we can give all our input to you to find the best solution for your products.